The company Brankamp was founded in 1977 and acquired by Marposs in 2012. Brankamp is now a brand managed by MARPOSS Monitoring Solutions GmbH and marketed through the Marposs worldwide network.

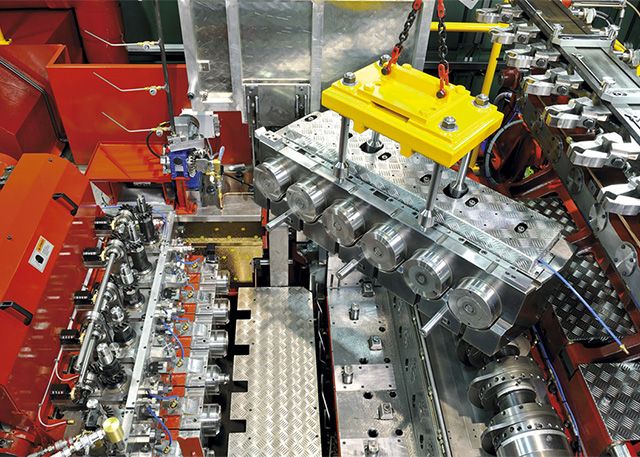

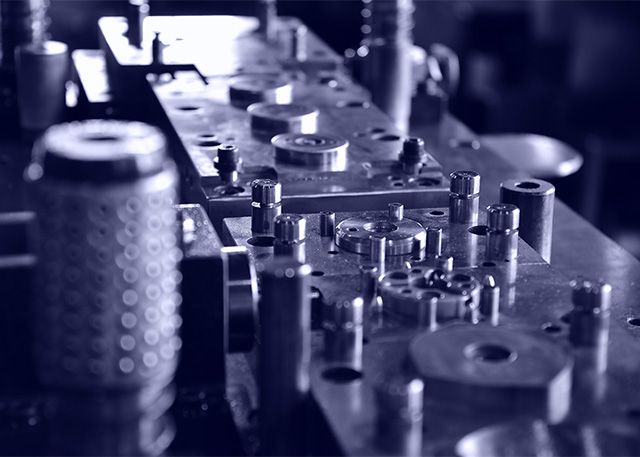

MARPOSS Monitoring Solutions GmbH is a global market leader of process monitoring, machine control and data collection, offering innovative technologies for in-process monitoring in the whole metal forming industry. Decades of experience in the cold forming-, stamping- and forging industry are embodied into the Brankamp systems to improve productivity, part quality and reduce production costs.

Subscribe to our newsletter

Receive news and updates about Marposs